Wood Fill PLA Pellets Tolerances Compared: Material Extrusion Report

Di uno scrittore di uomini misteriosi

4.6 (656) In Magazzino

Here is one for all you additive addicts out there! Wood and plastic are often placed conceptually as antithetical materials due to their contrasting qualities- endlessly variable vs.. homogeneous and consistent, natural vs.. synthetic\, traditional vs.. futuristic. the list goes on.. In spite of this, the truth is that wood is commonly combined with different polymers as a fine dust to great effect! If you have never tried it, it is worth a try just for the smell alone- and we've got some extrusion test results that can help guide you along your way with some baseline settings for success.. Join the wood/plastic fusion revolution! Test Technician: Nasser Abdel-FatahTest Number(s): ET200831NA01-Spool1 & Spool2Plastic Name: Wood Fill PLA PelletsMSDS: N/A Need to contact ManufacturerManufacturer: Push Plastics Supplier: Push PlasticsAdditives: WoodMaterial Form: Pellets, light brown. Extrusion Test Notes Material preparation: None. Grinding: None.Drying:

Here is one for all you additive addicts out there! Wood and plastic are often placed conceptually as antithetical materials due to their contrasting qualities

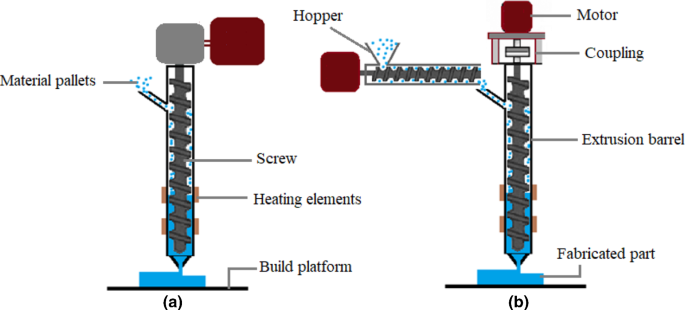

Extrusion-Based Technology in Additive Manufacturing: A Comprehensive Review

G-code Generated for (a) Filament extrusion and (b) Pellet extrusion, g1 f1500 e0

PDF) Influences of 3D printing parameters on the mechanical properties of wood PLA filament: an experimental analysis by Taguchi method

3D Printing of Sustainable Coal Polymer Composites: Study of Processing, Mechanical Performance, and Atomistic Matrix–Filler Interaction

Granule-based material extrusion is comparable to filament-based material extrusion in terms of mechanical performances of printed PLA parts: A comprehensive investigation - ScienceDirect

Additive Manufacturing of Metallic and Ceramic Components by the Material Extrusion of Highly-Filled Polymers: A Review and Future Perspectives. - Abstract - Europe PMC

Functional miscibility and thermomechanical properties enhancement of substituted phthalic acetylated modified chitin filler in biopolymer composite

Triple-color coextrusion PLA filament for 3D printing and 3D pen. Diameter of 1.75mm (±0.03mm) and weight of 2.2lbs (1kg). Includes three colors - silk PLA gold, green, and rose red - for a multicolor effect. Each color is evenly distributed throughout the filament, allowing for smooth transitions between colors. Made with high-quality PLA material, which is environmentally friendly and biodegradable.

RepRapper Triple Color Filament Dual Extrusion PLA Filament 1.75mm for 3D Printer, PLA Filament 1.75mm Multicolor Like Dual Color Rainbow PLA

Design of experiments to compare the reprocessing effect with Fused Deposition Modeling printing parameters on mechanical properties of Polylactic Acid specimens towards circular economy - Tanay Kuclourya, Roberto Monroy, Rafiq Ahmad, 2023

Design of experiments to compare the reprocessing effect with Fused Deposition Modeling printing parameters on mechanical properties of Polylactic Acid specimens towards circular economy - Tanay Kuclourya, Roberto Monroy, Rafiq Ahmad, 2023

Plastic Extrusion: Definition, Purpose, How It Works, Advantages, and Examples

Overview of fabrication method for PLA-PHA and cellulose acetate

Polymers, Free Full-Text

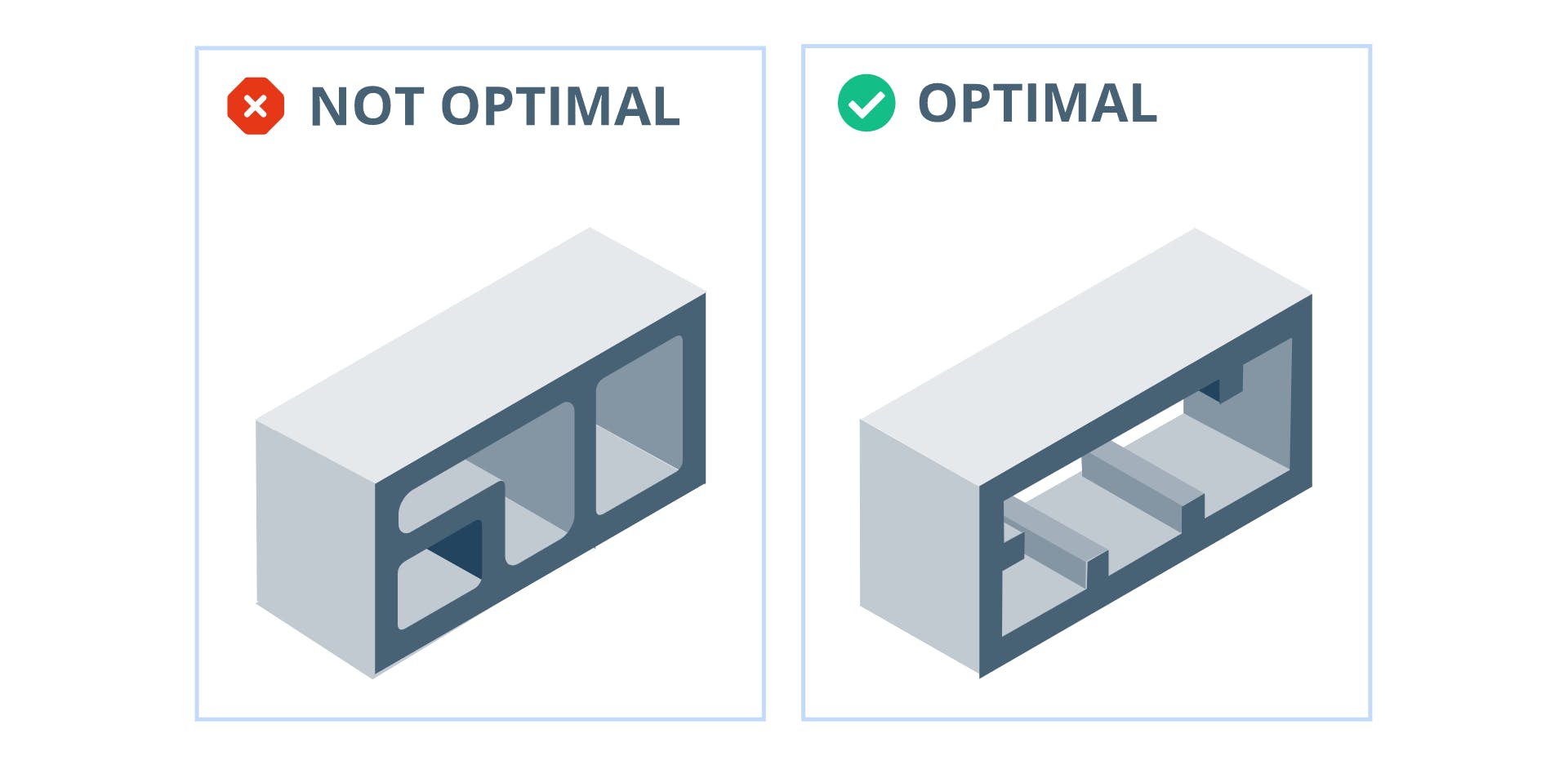

Enhanced Dimensional Accuracy of Material Extrusion 3D-Printed Plastics through Filament Architecture

PLA Wood 3-pack Forest - AzureFilm

PLA 3D Printing Filament Wood 3D Printing Filament 1.75mm 1KG

3D Printer Filament Bundle, Pla Filament Wood Filament, White Pine

Audio-Technica AT2020 – Thomann Italia

Audio-Technica AT2020 – Thomann Italia Matita da piantare - Margherita – Gioeca

Matita da piantare - Margherita – Gioeca Leonardo Sciascia (1921-1989), Italian writer and politician Stock Photo - Alamy

Leonardo Sciascia (1921-1989), Italian writer and politician Stock Photo - Alamy 12/16 Sacchetti Stoffa Trasparenti Satinati Sacchetti Regalo - Temu Italy

12/16 Sacchetti Stoffa Trasparenti Satinati Sacchetti Regalo - Temu Italy Excelsa Rainbow set 6 coltelli da tavola seghettati acciaio inox, bianco cod.46577 - Casalinghi Posate Coltelli Excelsa - Af Interni Shop

Excelsa Rainbow set 6 coltelli da tavola seghettati acciaio inox, bianco cod.46577 - Casalinghi Posate Coltelli Excelsa - Af Interni Shop Arva Zaino Tour Airbag 32L Grigio

Arva Zaino Tour Airbag 32L Grigio