MicroLED transfer technology explained

Di uno scrittore di uomini misteriosi

4.6 (262) In Magazzino

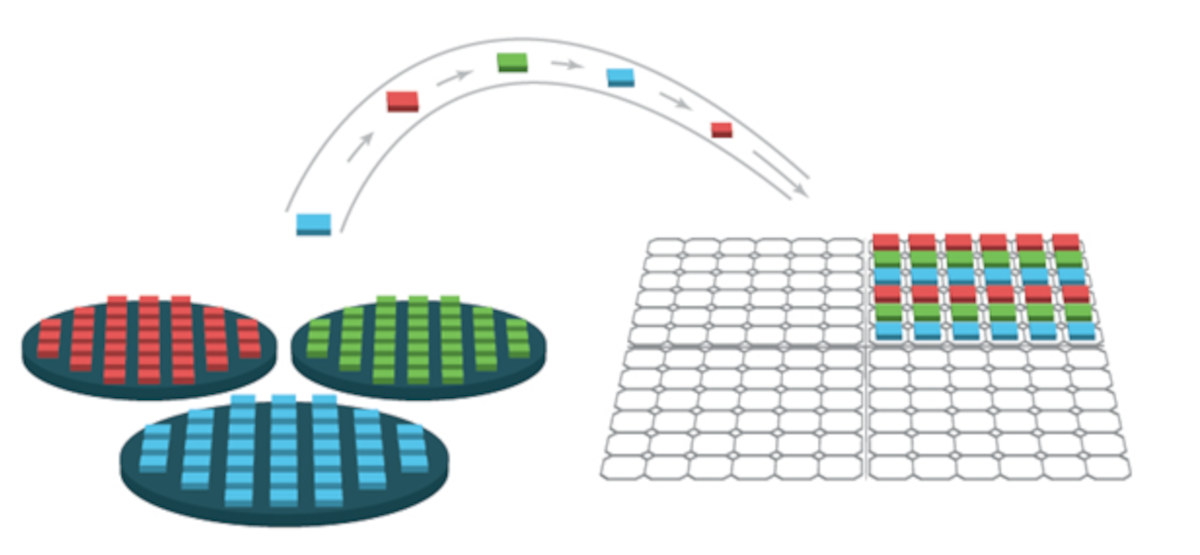

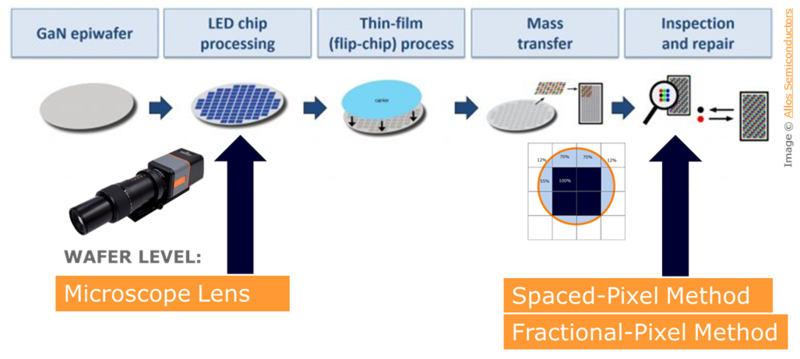

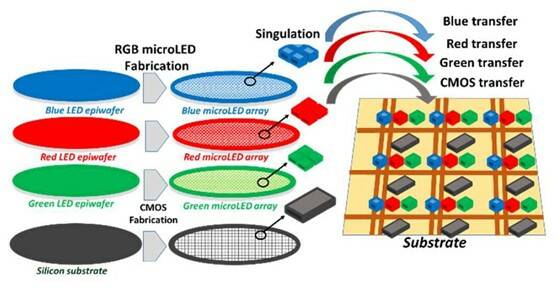

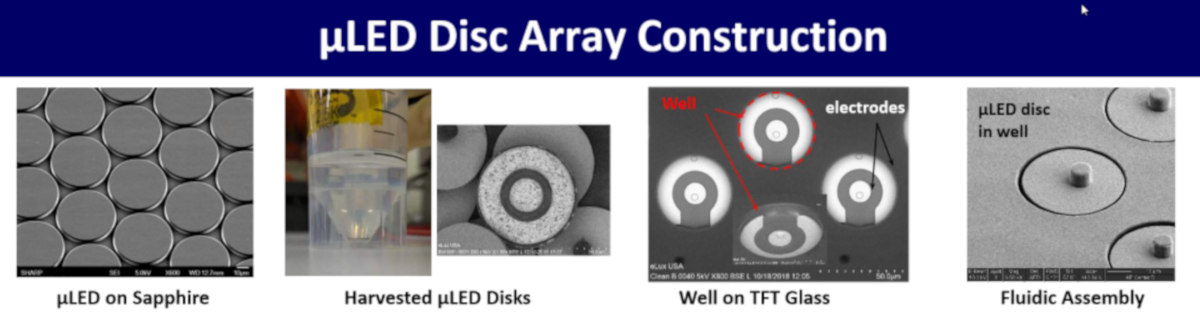

The microLED transfer process is crucial in MicroLED display production, this is likely to be the most challenging part of the entire process. In this article (an excerpt from The MicroLED Transfer Process Report), we'll give an overview of the transfer process, its challenges, and alternatives.At the beginning of this stage, there's the wafer with the MicroLED chips, and a display substrate with the backplane TFTs on top. As we said, this is a challenging process, and there are three main challenges in this step – accuracy, speed and reliability.It is important to note that if the display is based on RGB microLED devices, it complicates this step further – which is why many MicroLED makers are expected to adopt blue LEDs with color conversion. Accuracy is an obvious issue – a microLED chip is extremely small and needs to be placed in the right place with very little room for errors.Speed is another important consideration. Many displays today are of very high resolution – even smartphone displays are approaching 4K resolutions. A 4K display uses over 24 million subpixels. Even with mass transfer tools this is still a challenge as the display industry relies on quick and cost-effective production to achieve low costs.Reliability is of course important. In the current LCD and OLED industries, producers manage to achieve extremely high yields and as display resolution and sizes increase, yields become more critical. The microLED yield issue will be discussed in a section below.As can be expected for such a complicated process, several different technologies have been developed over the last few years. Most companies seem to focus on a stamp-based process. There are several ways to develop a stamp that can pick-up, hold, move and release microLEDs - using Van der Waals forces, using electrostatic charge, using magnetics, adhesives and more. Some companies look at novel ways to achieve the pick and place process - using fluidic assembly, or photochemical polymers. We will detail all public transfer process technologies below.Some researchers classify transfer processes as follows

Mass transfer for Micro-LED display: Transfer printing techniques - ScienceDirect

The Key Technology to Micro LED: Mass Transfer - LEADING LED TECH

a) Schematic drawings of the micro-LED platelets fabrication process

Crystals, Free Full-Text

Progress in MicroLED Displays

Progress in MicroLED Fabrication and Quality: Closing the Commercialization Gap

Mini and Micro LED Processing Technology

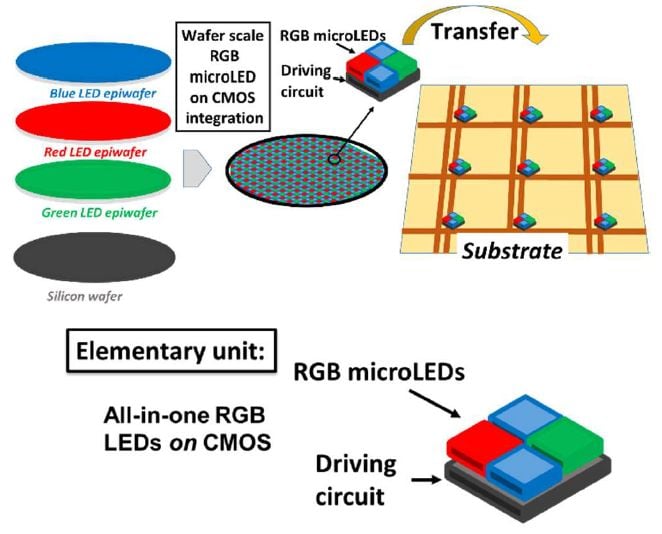

All-in-one RBG MicroLEDs and driver ease mass transfer process

Mini- & Micro-LED Displays: Markets, Manufacturing Innovations, Applications, Promising Start-ups, Virtual Event

MicroLEDs: The Next Revolution In Displays?

eLux's fluidic microLED technology and business explained

Integration Technology of Micro-LED for Next-Generation Display

The Key Technology to Micro LED: Mass Transfer - LEADING LED TECH

CES 2023] MICRO LED: The one and only

Micro LED TV: A Glimpse into the Next Generation of Visual Brilliance

a) (a) Illustration of flip-chip bonding between micro-LED array and

Designs of InGaN Micro-LED Structure for Improving Quantum

a) Schematic drawings of the micro-LED platelets fabrication process

Sgabello in Polipropilene Rinforzato con Fiberglass

Sgabello in Polipropilene Rinforzato con Fiberglass Niccol Ammaniti, Io non ho paura (Torino: Einaudi - campo7.com

Niccol Ammaniti, Io non ho paura (Torino: Einaudi - campo7.com Spurgofreni E Frizioni Pneumatico A 3 Camere. - 010805 - Auto Attrezzature Triveneto

Spurgofreni E Frizioni Pneumatico A 3 Camere. - 010805 - Auto Attrezzature Triveneto SGABELLO CON SCHIENALE PER ESTETISTA MANICURE CENTRO ESTETICO WEELKO PRACTI+

SGABELLO CON SCHIENALE PER ESTETISTA MANICURE CENTRO ESTETICO WEELKO PRACTI+ F-104 storia di un mito

F-104 storia di un mito Alpinestars Tuta Moto Racing Gp Plus V2 Bianco giallo rosso Fluo Pelle Intera 48

Alpinestars Tuta Moto Racing Gp Plus V2 Bianco giallo rosso Fluo Pelle Intera 48